How Bread is made? - Preparation and Ingredients

Bread is made out of four main ingredients: flour, water, salt and baker's yeast. Some other ingredients and improvers can be added to change the taste and texture of the bread but if you have these four - you can make bread.

First, ingredients are measured. Recipes that give measures most often do that in so-called “baker's percentage”. The amount of flour is given to be 100%, and the amounts of the other ingredients are expressed as a percentage of that amount by referring to weight. Measurement by weight is more accurate and consistent than measurement by volume, especially for dry ingredients. Measured ingredients are then mixed together. Mixed compound is then kneaded. When the mixture is uniform and becomes dough, it is left for yeast to ferment. A lot of recipes tell to let dough sit in a warm place until it doubles in bulk. When the dough has risen it is gently kneaded again to gently press out the gasses in the dough and redistribute the yeast. After that, if there is dough for more than one loaf, dough is divided in pieces of desired size. If fermentation has heated up the dough, it is then left to rest for some time. Dough is then placed in the pan, proofed (left in the pan, covered, to rise some more) and then baked. When finished, bread is left to cool and then stored.

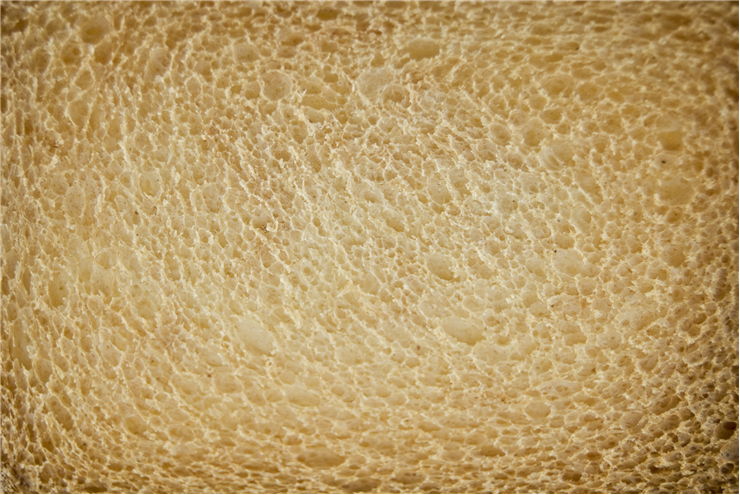

Different ingredients give different properties to bread. Flour gives bulk and structure to the bread. It has two proteins, gliadin and glutenin which, when are mixed with water, combine and give gluten which helps yeast grow. Yeast are single celled organisms that ferment some of the carbohydrates in the flour, including any sugar, producing carbon dioxide which rises the dough. Salt is put in the dough to give bread flavor but it also inhibits yeast growth. Additional ingredients can be also used. Fat can inhibit gluten formation and bread will not rise quite as high but fat adds a lot of flavor, makes bread softer and extends its shelf life. Eggs, on the other hand, help with rising. Sugar, of course, makes bread sweeter but it also gives crust more brow color, can make the bread softer and, because it holds onto moisture, makes bread last longer if left. Instead of water, in some parts or all, milk can be used. It makes bread sweeter and adds additional proteins. For more special kinds of bread, many different ingredients can be added in the dough, from fruit, vegetables, nuts or seeds. Imagination is the limit. Crust of the finished product can be different, depending on the treatment of the finished bread. Crackly, shiny crust can be got by any of the different methods of steaming. Soft crust is got if the bread is not treated with steam or water. Golden, shiny crust is got by applying an egg wash. If the crust is brushed with milk with a little sugar, it will be soft and sweet. For sweet and sticky crust bread is brushed with syrup or honey and for shiny and soft crust with olive oil.

Bread can be made by hand but in commercial production it is made by machines. Then are often added bread improvers and dough conditioners to reduce the time needed for rising and to improve texture and volume. Chemical substances commonly used as bread improvers are ascorbic acid, hydrochloride, sodium metabisulfate, ammonium chloride, various phosphates, amylase, and protease.